19.06.2025

IoT learning environment

Is it time to replace the bearing?

The field of mechanical and production engineering offers many interesting areas for applying IoT in condition monitoring. For example, keeping a large fleet of equipment in operation is challenging, as the machines should remain in working order at all times without long interruptions.

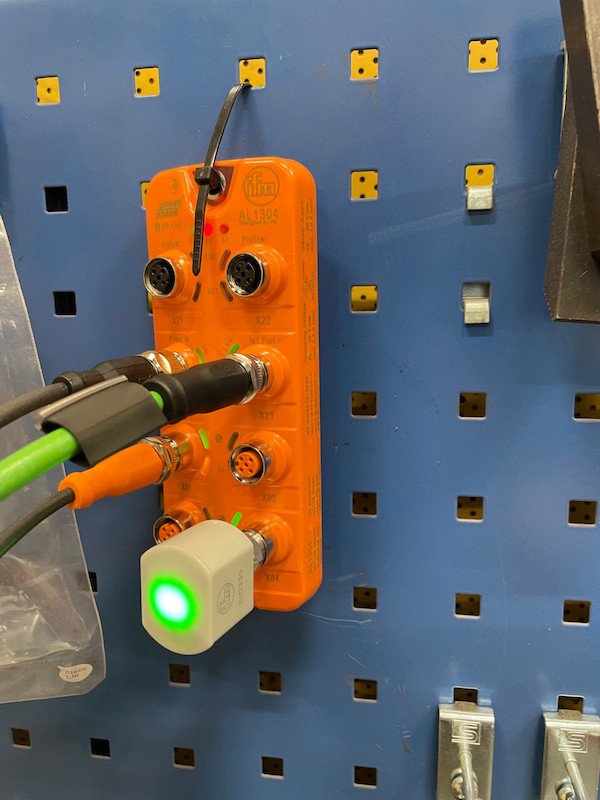

The IoT learning environment project is testing how the condition of equipment can be monitored in a new way using IoT. The experiment involves a vibration sensor that is placed on a machine to determine, for example, whether it is time to replace a "worn out" bearing with a new one.

The vibration sensor currently in use is the VVB301, which is screwed onto the machine. The vibration sensor measures typical industrial v-RMS(x,y,z) and a-Peak values, which indicate the average vibration of the device and the peak vibration values. The vibration sensor thus detects different types of vibration during device use, indicating when the device requires maintenance.

The vibration sensor data is transmitted via the Io-Link master to the university center's cloud platform, where vibration data is collected over a longer period of time. When maintenance is required, the system alerts the user.

News related cases

IoT learning environment in the field of mechanical and production engineeringExtra information

Jukka Määttälä, university teacher